"Where Steel Meets Shield - Trusted Galvanizing Solutions."

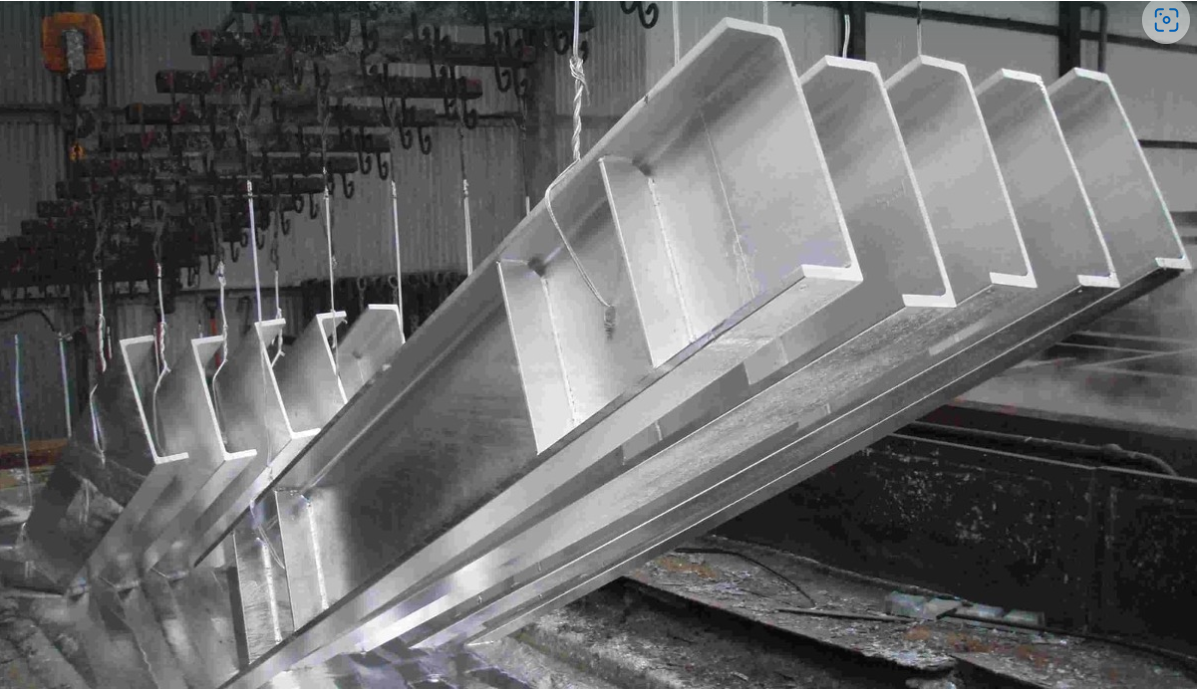

Geared to the needs of modern Industry in the Gulf area, we are pleased to introduce ourselves to your esteemed organization hoping to be able to satisfy your requirement in the field of hot dip galvanizing. We are pioneer leader and offer the best service for Hot dip galvanization of Mild steel Structures of various shapes and sizes suitable to Molten Zinc bath size. Hot dip galvanizing is the ultimate in anti-corrosion protective coating; it gives a tough reliable coat with long maintenance-free life, clean appearance, low cost and time saving job. GSE is a member of the International Galvanizers Association of America and UK. Our Galvanizing facilities offer various protective coating services. Materials up to 14mtr length and up to 4mtr in height can be Galvanized at our plant, which has a capacity of 3000 tons monthly.

OUR MISSION:

To deliver world-class galvanizing solutions that enhance the durability, strength, and sustainability of steel structures. We are committed to quality, innovation, and customer satisfaction while maintaining the highest safety and environmental standards.

OUR VISION:

To be the leading galvanizing company recognized for excellence in corrosion protection, innovation, and customer service, setting industry standards and contributing to a more sustainable future.

We specialized in

- Hotdip Galvanization and anti-corrosion activities

- Painting Operation

- Airless Spray Painting of steel items

- Abrasive Blasting

- Fireproof Painting

Happy Clients

Projects

Hours Of Support

Hard Workers

Services

Featured Srvices

Hot Dip Galvanizing

Hot dip galvanizing is a galvanizing process by which the steel is coated with a

layer of

zinc to be corrosion-resistant.

Hot dip galvanizing is an economic and efficient method of protection of iron and steel from

rust and corrosion, prolonging its life, and reducing maintenance costs.

Abrasive Blasting

Abrasive blasting (or sandblasting) is a surface preparation method that uses

high-velocity abrasive particles to remove rust, dirt, or old coatings.

It leaves the surface clean and textured (Sa1-Sa3) for better coating adhesion.Surface preparation

procedure mechanically by bombarding/spraying.

Sweep Blasting

:Also known as brush or whip abrasive blasting, is a gentle abrasive blasting

process used to prepare surfaces, particularly galvanized steel, for painting or other

coatings.

Airless Spray Painting of Steel items

Airless spray painting is a process by which steel products are sprayed with

paint.It utilizes a pump to pressurize paint, and then it is pushed through an extremely small

nozzle and forms a fine spray. It does not utilize compressed air, as with regular spray

painting. Benefits:

1. Quick application.

2. Thicker coats

3. Smooth finish

4. Protection against corrosion

5. Durability

6. Efficiency

Fire Proof Painting

Fireproof painting, or fire-resistant painting or intumescent painting, is a

specialized coating

painted on surfaces for protection against fire. The paint in question is specially designed

to:

- Retard fire spread

- Maintain structural integrity: As a protective shield against

fire and heat

- Meet safety requirements.

Fireproof paints typically contain specialized

components that:

1. Swell or expand with the application of heat

2. Provide thermal

insulation.

Fireproof painting is extensively used in:

1. Industrial complexes: Such as

oil refineries, chemical plants, and power houses.

2. Commercial complexes: Skyscrapers,

shopping malls, and other structures wherein fire protection is essential.

3. Steel frames.

Epoxy Painting

Epoxy paint is a type of paint that utilizes epoxy resin as the main component.

The following are

the features of epoxy paint: Key Characteristics:

-Epoxy paint has high resistance to wear

and tear, chemicals, and abrasion.

- Adhesion: The epoxy paint has good adhesion to

different surfaces such as metal, concrete, and wood.

- Chemical resistance: The paint based

on epoxy is chemically resistant to many acids, bases, and solvents.

- Glossy finish: Epoxy

paint can give a glossy finish that is not only visually appealing but also easy to clean.

Uses:

1. Industrial floors are typically coated with epoxy paint, which is a

chemical-resistant and durable coating.

2. Steel structures

3. Marine applications

Surface Preparation

surface preparation is a critical step to ensure proper zinc coating adhesion.

The typical methods include:

1. Degreasing – Removes oil, grease, and dirt using alkaline or acidic solutions.

2. Pickling – Removes rust and mill scale using dilute hydrochloric or sulfuric acid.

3. Rinsing – Washes off chemicals between steps to avoid contamination.

4. Fluxing – Applies a zinc ammonium chloride solution to prevent oxidation before galvanizing.

5. Drying – Ensures the surface is dry before dipping in molten zinc.

Each step is vital to achieve a clean, reactive surface for optimal hot-dip galvanizing results.We

offer a full range of surface preparation and protective coatings

Portfolio

CHECK OUR PORTFOLIO

Team

CHECK OUR TEAM

Our Strengths

Innovative Approach: Our every branch firm is inspired to innovate and stay ahead of the curve.

Synergies

Our branches operate together to work on each other's strengths and capabilities.

New Locations

We're Growing Stronger...

We're expanding into new regions.

Contact

Reach out to us at either of our offices for all your galvanizing needs.

Galvanizing Services LLC

P. O. Box 6647, AL Quoz Ind.-3,Dubai, United Arab Emirates

Call Us

+971 4 34 70 602

Email Us

sales@galvserv.com

Galvanizing Services FZE

Free Zone Establishment, P.O. Box 41974,Free Zone, Phase-1, Sharjah-UAE

Call Us

+971 6 546 5207

Email Us

sales@galvservfze.com